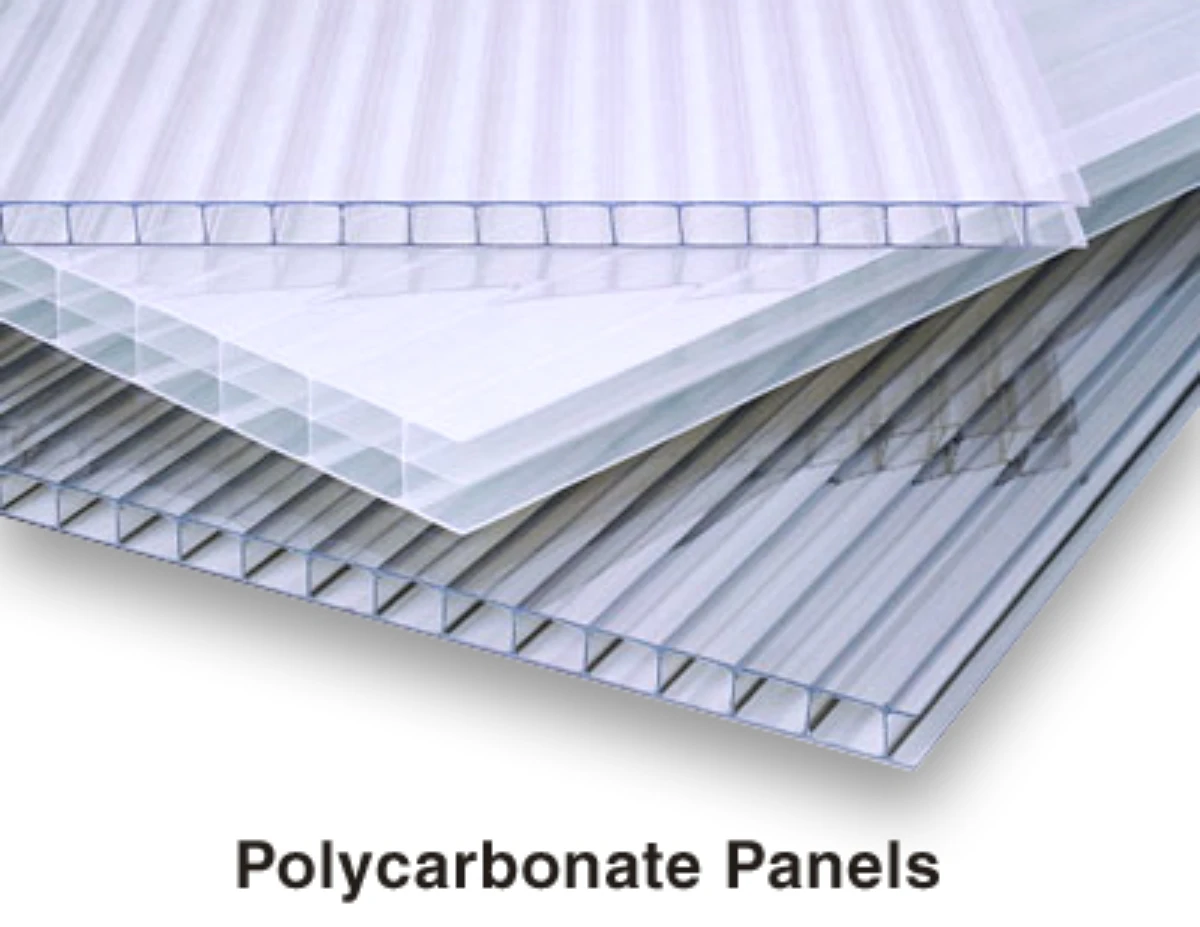

POLYCARBONATE PANELS

Buy polycarbonate panels, sheets locally for your greenhouse, patio covers and other backyard projects for polycarbonate applications. Best choice, high tensile strength, extreme flexibility and high impact resistance. Available for U – pickup… in stock.. call 719 270 3000 ….

Polycarbonate history….

The polycarbonate discovery became known somewhere around 1954 (I was 4 years old) by Dr. Hermann Schnell. He worked at Bayer in Germany and soon after it was also discovered by Chemist Daniel Fox from General Electric. Ironically they both discovered the same gooey substance within days of each other. Apparently, polycarbonate originated as a resin polymer made from mixing bisphenol A with phosgen. After it harden it transformed into an almost indestructible material. In the early days, polycarbonate was termed Lexan. Just about everyone today has heard of this term and now that the greenhouse industry has grown over the years. Lexan sheeting is now referred to as polycarbonate panels, or polycarbonate sheets.

POLYCARBONATE VERSATILITY

The structure of polycarbonate lends itself to many applications. Polycarbonate panels and related products consist of polymers and carbonates. Due to the strength and flexibility of these compounds, its development in essence, has proved to be highly appropriate. For uses in eye wear lenses, bullet resistant glazing, airplane windows and in many micro electrical components. Colors are also available… ! Special order

Over the years, and as researchers learn more about polycarbonate, It has become particularly useful in applications that call for transparent applications.

Glazing applications such as in the aircraft industry, the automotive industry, the eyeglass industry and the cell phone industry.

As well in transparent packaging for the DVD and blue ray disc industry and a variety of other installations.

The flexibility and variations on how polycarbonate can be transformed into various uses, made this product acutely in demand, in many industries.

POLYCARBONATE PANELS FOR GREENHOUSES

The most common use is widely seen in the construction industry. Due to its high tensile strength, extreme flexibility and high impact resistance. It was not long after its discovery that polycarbonate panels could replace the use of glass in many applications.

As we can now surmise, greenhouse applications always used glass. Greenhouse glass allowed for direct sunlight transmission which is essential for greenhouse plant growth.

However, glass, back in the day. Events such as weather and UV degradation due to intense sunlight, breakage due to direct impact and physical weight had many shortcomings.

POLYCARBONATE PANELS

POLYCARBONATE BENEFITS

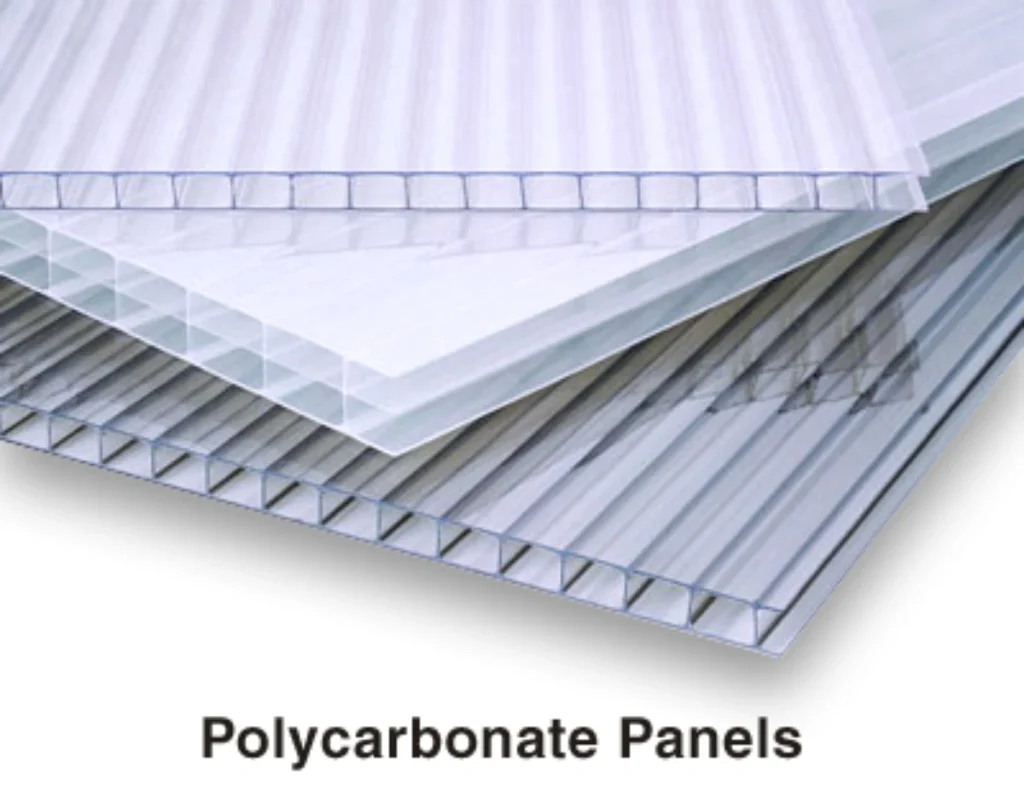

As the industry developed. Polycarbonate was co-extruded into panels of various dimensions such as in width, length and thickness.

Multi wall polycarbonate sheets come in a variety of lengths and thickness’s and all have unique R-value and U-value properties. See technical data above….

The light weight physical properties make these panels ideal glazing applications.

Loading: here is an informative chart on how to space your horizontal support framing…

Loading requirements need to be determined based on local conditions and codes. The framing structure holding the multi wall polycarbonate must be constructed to support these loads and its details are independent of this document.

The maximum sheet deflection is often the limiting factor for multi wall polycarbonate sheet. The chart below indicates maximum spans for a max 1” deflection at several different loads. The details of this loading and the max spans will be project specific. Other loading documents are available if the conditions require.

APPLICATIONS AND PROPERTIES

Most noteworthy in dome and skylight glazing, flat and curved glazing applications, translucent roofs, walls and specifically for greenhouse roof applications.

Polycarbonate now abundantly common and widely used globally for outdoor applications.

Translucent applications require UV inhibitors. A specific surface treatment which makes for a long lasting roof glazing applications and provides long life durability.

UV exposure and constant exposed weathering make polycarbonate the ideal product for greenhouse roofs and sidewalls.

Polycarbonate Lexan has evolved and has replaced many traditional materials and continues to provide many benefits to everyday applications. Its strength and durability to this day remains unmatched in all forms of its applications and uses. It is no wonder that the greenhouse industry has embraced poly-carbonate panels as the glazing material of choice.

Over the course of time…. I get questions like ..whats stronger acrylic or polycarbonate …?

In short, polycarbonate is still evolving and as a result, will probably continue to be in high demand. Bayer and General Electric remain at the forefront of its development and as product designs improve and technology continues to develop, glazing applications will only get better.

H- Channels, U-channels and breather tape …. how important are these? for a good and long lasting installation …

Please remember these key components when ordering …

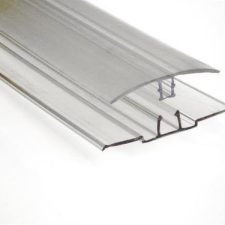

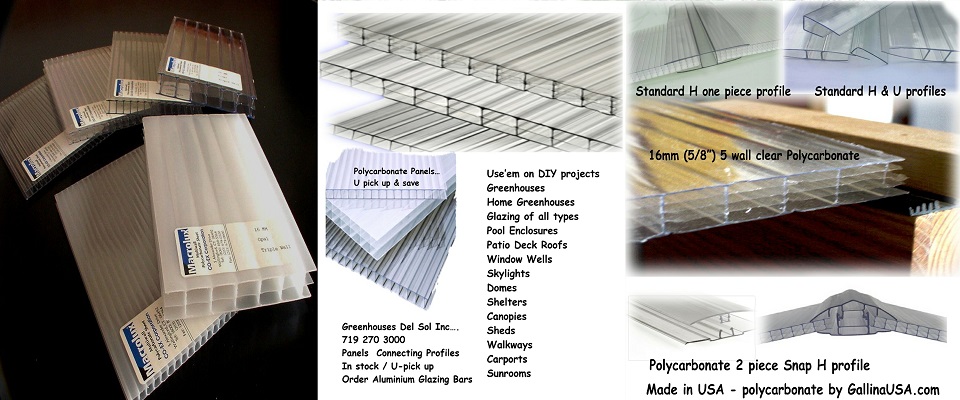

H-channels are available in polycarbonate material .. this is the best bang for your buck…. there are 2 different types of polycarbonate H-channels…

• one piece-single profile – cheapest , available in 6mm, 8mm, 10mm, and 16mm thickness

• two piece base and snap cap profile with or without glazing fin rubber .. see pics below … more cost…

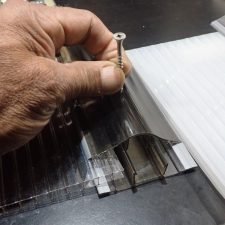

If you elect to use the 2 piece snap profile, in addition to relying on the snap function, best to also apply stainless steel screws through the center of the cap and through the base to fasten the H – channel securely…to your supporting rafter. Apply clear silicone caulk to the screw head too..!

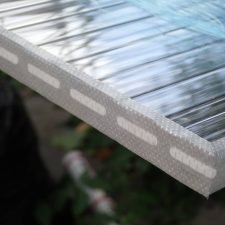

U-channels - Breather /aluminum tape -

Polycarbonate U-channels are the least expensive option, best to tape your ends then apply the U-channels over the tape… By doing this …this will protect the inside air space flutes of your panels by keeping them clean and free of particle dust and tiny bug build up over time…!

A word about condensation….! The following is an email exchange I had with a previous customer regarding condensation:

“what you have here is condensation …! this happens over at my house too…! frost builds up on our windows…and bottom ends of our polycarbonate panels when it’s very cold outside ..

today it was 1 degree outside., and when the sun comes out, condensation dissipates …and drips everywhere.

thus the reason for keeping wood trim away from the glazing …with glazing H & U channel/profiles….

the following are reasons for this situation ….?

To prevent condensation in a glazed space of walls and/or roof you need a continuous source of warm fresh air.”

Condensation within the air flutes of clear poly-carbonate panels, is almost inevitable..? for this, apply breather tape to the bottom end of the panel and solid aluminum tape at the top end of the panel, both for roof or walls. The tapes seal the top end while the bottom end allows air through the flutes to dry up condensation. Apply U-channels over the tape, secure U-channel with # 6 /ss screw /nail to wood -18” apart, apply clear silicone bead across the (full width of the panel) on the top edge of the U channel and panel ..end to end ..! Condensation occurs in most applications but can be controlled and minimized in most situations employing these recommendations.

Buy polycarbonate panels locally for your greenhouse project…! For current pricing and availability

please call 719 270 3000 …

Reference Polycarbonate material links:

Consumer benefits and info

Polycarbonate History

Panel Pricing Page